Predictive maintenance of smoke extractors in OMRON's automotive body shop

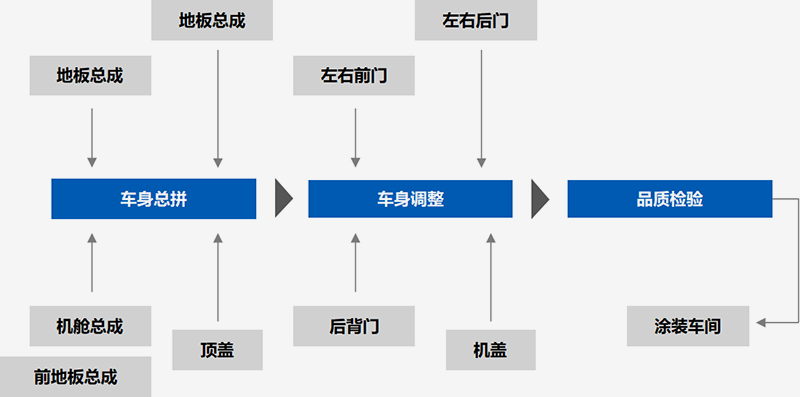

Process Introduction

Automotive body welding is the second of the four major processes in vehicle manufacturing, mainly assembling the stamped body components into a complete body. In the welding process, robot spot welding and arc welding are mainly used, and there will be a station for visual inspection of the welding status.

As one of the leading automobile manufacturers in China, the company has a very high market share and therefore expects to improve the stability, operating rate, and safety of its equipment at the business level, while reducing the total investment cost.

Solution

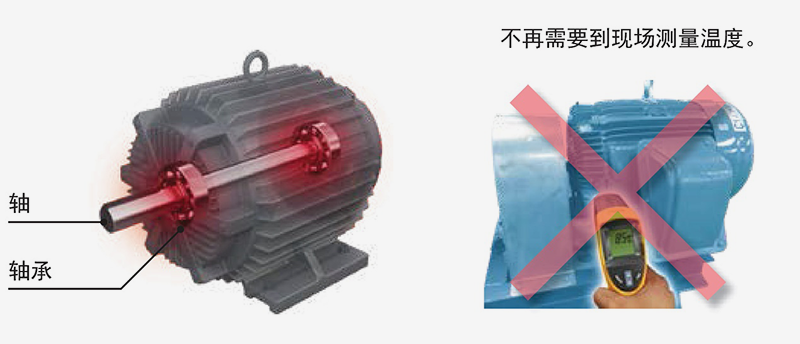

1 Monitor bearing abnormalities through vibration and temperature

By continuously monitoring vibrations, signs of bearing abnormalities can be quickly detected. In addition, the surface temperature of the motor checked daily can also be measured simultaneously.

Can measure up to 10kHz vibration frequency, so motor abnormalities can be detected early.

2 Comprehensive monitoring of motor and load abnormalities according to the degree of aging

Calculate the degree of aging using two algorithms 1 and the degree of aging 2 to monitor abnormalities in a composite manner.

Degree of aging 1:

Suitable for monitoring abnormalities that irregularly affect the motor shaft, as it can convert the deviation between the entire current waveform data collected during sampling and the ideal sine wave into a numerical value.

Degree of aging 2:

Specific frequency components can be clearly captured from the frequency components affecting the motor rotating shaft and converted into numerical values, so it is suitable for monitoring regularly occurring abnormalities. Even in environments with inverter interference, abnormalities can be detected with high sensitivity. 。

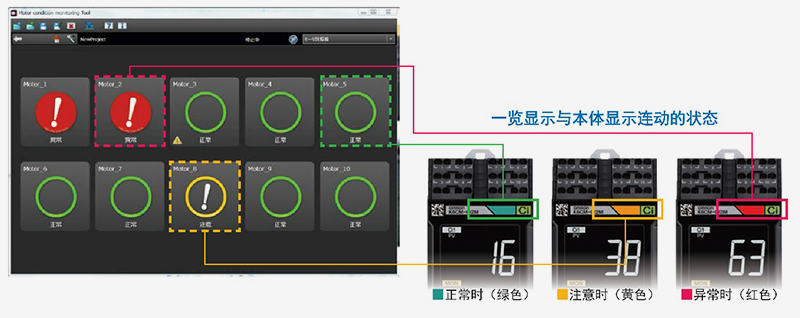

3 Motor status at a glance through dedicated monitoring software

Through the networked K6CM series, the status of up to 10 motors can be displayed at a glance. Up to 30 data can be browsed. K6CM ( 1 can be installed on 3 motors. K6CM )

Displays the alarm status of multiple motors, and allows confirmation of changes in motor status in chronological order. Trends in measured values can be grasped through charts. (Measured and accumulated data can be output in CSV format, which is very useful for creating reports and statistics.)