SMC contributes to hygiene management in the bread processing process

Baking Process Flow

From ingredient handling, mixing, dividing, primary fermentation, shaping, secondary fermentation, baking, slicing to packaging.

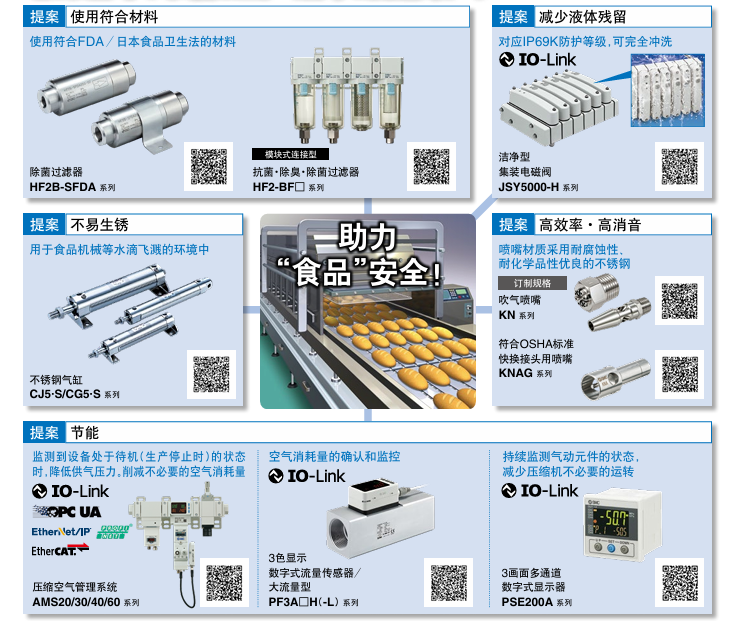

1. Using materials that comply with food hygiene regulations

As compressed air comes into contact with the entire food production process, it is key to ensuring food safety. To ensure that the quality of air source treatment in automated solutions meets standards, SMC The product uses materials that comply with FDA/ Japanese food hygiene regulations

Sterilization filter HF2-BF Is based on HACCP and other standards designed for hygiene management, with good antibacterial, deodorizing, and sterilization functions, currently used in dental equipment and when air comes into contact with food.

Sterilization filter SFDA Series with hollow fiber filter cartridges, filtration accuracy up to 0.01 μ m (Collection efficiency 99.99% ),used to remove bacteria from compressed air. (Bacterial capture performance LRV ≥ 9 ※ 1 ) The main body uses materials that comply with FDA and Japanese food hygiene regulations ※ 3 ,no grease. Suitable for direct air blowing to food 。

2. Reduce liquid residue

In terms of food safety, its production process is paramount, and equipment needs to reduce liquid residue and meet high-intensity cleaning requirements. If used in situations with splashing water droplets, the product's long lifespan and clean design must be ensured, and it must be easy to clean, install, and maintain.

3. Corrosion-resistant design

Under the high standards and strict requirements of food hygiene regulations, the supporting pneumatic components must have high corrosion resistance to cleaning solutions (such as hydrogen peroxide), filled beverages, environmental impurities, and ozone used for workshop sterilization.

4. Improve equipment efficiency

SMC It can provide maximum flexibility and reliability during continuous air blowing and culling, improving equipment efficiency.

5. Energy saving improvement

SMC Energy-efficient and high-efficiency pneumatic products help companies improve energy efficiency and reduce operating costs.